Case Study: Manville’s Winding Expertise

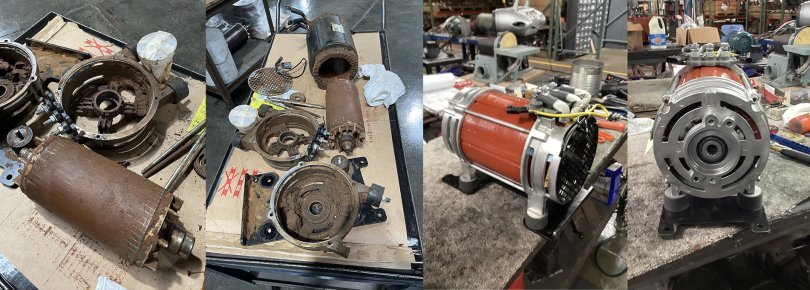

Motors see a lot of different kinds of dirt and dust, but nearly none as bad as this one. Full of nearly petrified sawdust, this motor was completely impacted and useless. And it’s a forklift motor that has a lot of wire in a tiny space.

The job was too much of a challenge for another shop, so they turned to Manville. The project was no problem for us, and we were able to repair the impacted motor and turn it around in 4 days.

“Getting tough jobs done in a short timeframe is what sets us apart,” said Brooks Adams, President of Manville Material Handling Solutions. “When it comes to winding, machining and building motors, we have one of the most talented teams around. It’s nice to know that we can tackle almost any electric motor problem out there, and do it quickly and accurately.”

For 39 years, Manville Electric Motors has been a leader for rebuilt electric motors. Now we also provide intelligent lift systems, and light rail cranes, autonomous mobile robots and much more.

Manville recently moved to its new location at 188 Chandalar Place Drive, Pelham, AL 35124.

Contact Brooks Adams at 866-503-5171 or visit manvillesolutions.com for more information.